Different businesses and fleets operate with unique vehicles, site layouts, and service goals, which means no single Car Wash Machine fits everyone. From compact city cars to heavy-duty buses, from high-throughput tunnels to space-saving gantries, the right machine depends on matching technology with vehicle size and operational priorities. Shenyang Cheer Wash Equipment Co., Ltd. offers a complete line of automatic car wash solutions, giving business owners and fleet managers flexible choices to optimize cleaning performance, lower costs, and deliver consistent customer satisfaction.

Quick overview: main Car Wash Machine categories

Selecting a machine starts with knowing the main categories available in the market. Each type has its strengths and is suited for specific vehicle sizes, site conditions, and operator requirements.

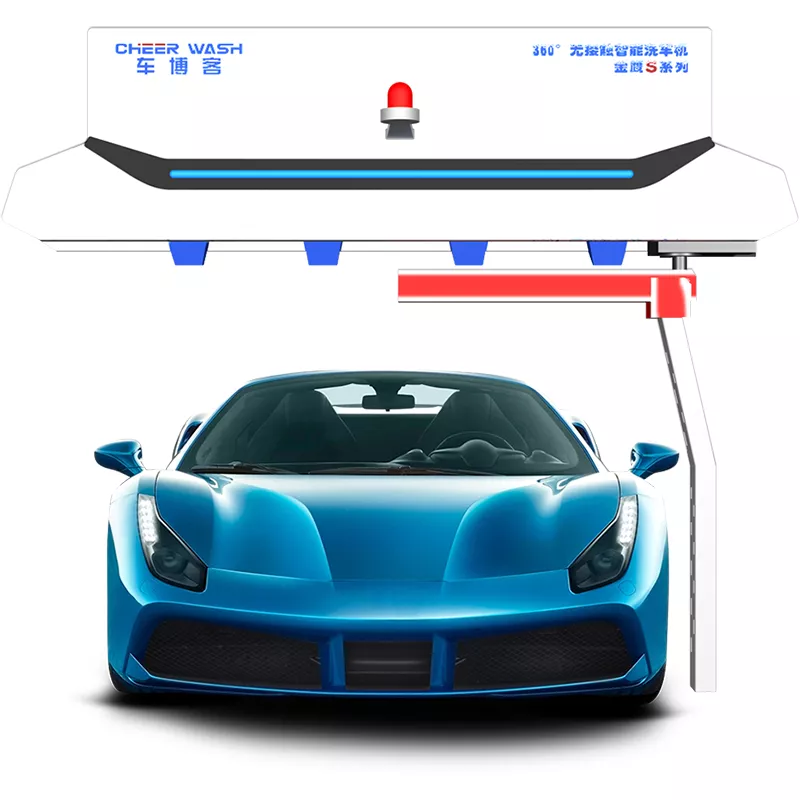

Touchless or touch-free systems

These machines rely on high-pressure water jets and detergents instead of brushes. They are favored for delicate paintwork, coatings, and customers who prefer a zero-contact wash. They reduce the risk of scratches but depend heavily on chemical dosing and water pressure. For operators who want to highlight a premium “safety-first” wash, touchless systems are an attractive option.

Soft-touch or cloth systems

Soft brushes or cloth strips physically agitate dirt for a thorough clean. They are reliable for everyday vehicles and deliver consistent results. Many operators choose them for busy stations where visible results in a short cycle time are important. Advanced versions combine cloth agitation with touchless rinsing to balance safety and speed.

Rollover (gantry) machines

A rollover gantry moves back and forth over a stationary vehicle. They are compact, require less site space, and are common at fuel stations or small businesses. They balance affordability with quality, making them popular for mixed-use sites. Newer models also integrate contour-following technology to improve coverage on taller or irregularly shaped vehicles.

Tunnel or conveyor systems

Tunnel systems move the car through multiple cleaning stages while conveyors guide the vehicle forward. They are designed for high throughput, handling dozens of cars per hour. Dealerships, large stations, and professional wash centers often rely on them. With modular design, operators can add waxing, drying, or polishing stages as their customer base grows.

Bus and truck wash systems

Specialized large-frame machines handle oversized vehicles. They include longer brush arms, extended water spray coverage, and programmable settings for buses, trucks, and coaches. For operators serving fleets, logistics hubs, or public transport systems, these machines are essential. Their heavy-duty build ensures reliability even under continuous operation.

![CL800]()

Matching machines to vehicle sizes and needs

Vehicle size directly influences which Car Wash Machine makes sense. At the same time, business model and throughput goals also matter.

Compact and city cars: small-footprint machines or in-bay automatics

For urban sites with limited parking or narrow lanes, compact machines are ideal. An in-bay automatic, such as a gantry unit, allows efficient washing in tight spaces. Operators serving mainly compact cars or sedans can maximize space utilization without compromising wash quality. Touchless options also fit well here, offering gentle yet effective cleaning for smaller vehicles and ensuring high turnover in dense city areas.

SUVs and light trucks: medium-duty rollover or compact tunnel options

SUVs and pickups are larger and require machines that accommodate higher ground clearance and wider frames. Medium-duty rollover systems with adjustable brushes or contour-following jets can adapt to varying vehicle profiles. Compact tunnel options also serve operators in suburban areas where SUVs are common, providing a faster cycle time while handling more vehicles per hour. For businesses that cater to mixed families and personal trucks, this versatility is a significant advantage.

Fleet operators and dealerships: high-throughput tunnel systems

Car dealerships, rental agencies, and fleet operators prioritize consistency and speed. Tunnel systems, with modular washing stages and continuous conveyors, allow them to maintain clean fleets with minimal downtime. For these users, throughput is critical—measured in vehicles per hour—and tunnels are unmatched in efficiency. With options for waxing, drying, underbody wash, and wheel cleaning, they provide the professional finish demanded by fleet customers and enhance brand presentation.

Buses and trucks: heavy-duty wash systems and bus-friendly features

Large-scale operators such as public transport companies, logistics hubs, and coach services need specialized bus and truck wash equipment. These machines are engineered with extended arches, longer brushes, and powerful pumps to cover tall, wide vehicles. Features like side contour following and high-mounted drying units ensure no area is missed. For businesses with mixed fleets, having a bus-friendly machine ensures that both trucks and smaller vehicles can be serviced on-site, maximizing equipment utilization.

Operational metrics that matter when comparing machines

Choosing a Car Wash Machine is not just about size—it is about how the equipment performs day to day. Buyers often focus on several operational metrics.

Throughput (cars per hour): Tunnels can process dozens of cars per hour, while rollover units handle one car at a time. Matching throughput to expected customer flow prevents bottlenecks and ensures customer satisfaction.

Footprint and site layout: Gantry machines need less ground space, while tunnels require a long, straight layout. Bus wash systems demand larger clearances and extended bays. Planning the site in advance helps maximize land use efficiency.

Water and energy consumption: Efficient systems recycle water and use optimized spray nozzles, reducing costs and environmental impact. Energy use also matters when dryers and pumps run at high capacity, especially in large tunnels.

Maintenance cadence: Some systems require daily checks, while others are designed with lower-maintenance components. Predictive maintenance sensors are now being introduced to help operators reduce downtime.

Staffing requirements: Fully automated machines may need only minimal staff supervision, whereas tunnels with manual prep may require additional workers. Factoring in labor cost helps create a realistic operational budget.

Buyer checklist and procurement tips

When planning an investment, considering long-term value is just as important as initial cost. A few checklist items guide smart procurement:

Warranty length and coverage: Ensure critical components like pumps, motors, and brushes are protected.

Service network: Reliable after-sales service reduces downtime and keeps operations smooth.

Spare parts availability: Fast access to parts avoids long wait times during maintenance.

Uptime guarantees: Some suppliers commit to service-level agreements that minimize interruptions.

Modular upgrade options: Systems that allow future expansion, such as adding drying units or wax modules, extend the lifespan of the investment.

Training and technical support: Comprehensive training ensures staff can operate and maintain the machines effectively, protecting the investment over time.

Cheer Wash product mapping

Shenyang Cheer Wash Equipment Co., Ltd. has developed a comprehensive product line to fit every scenario. Buyers can easily match their operational needs with the right Cheer Wash solution:

360° touchless machines: Perfect for compact cars or customers demanding paint-safe cleaning.

Contour-following machines: Ideal for SUVs, pickups, and vehicles with irregular profiles.

Rollover (gantry) machines: The best choice for fuel stations or urban sites with limited space.

Tunnel car wash systems: Built for dealerships, high-volume stations, and fleet operators needing high throughput.

Bus and truck wash machines: Designed for heavy-duty performance, covering oversized vehicles with reliable efficiency.

Conclusion

Selecting the best Car Wash Machine requires aligning vehicle sizes, site conditions, and business goals with the right category of equipment. With solutions ranging from compact gantries to high-throughput tunnels and specialized bus wash systems, Shenyang Cheer Wash Equipment Co., Ltd. provides reliable, proven machines trusted worldwide. To explore which machine best matches your operation, contact us today for a tailored proposal and site planning consultation.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

Nederlands

ไทย

Polski

Türkçe

አማርኛ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Čeština

қазақ

हिन्दी

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Latine

اردو

Shqip

বাংলা

Afrikaans

සිංහල

नेपाली

Oʻzbekcha

Azərbaycan dili

Беларуская мова

Български

ქართული

Македонски

Wikang Tagalog

isiZulu